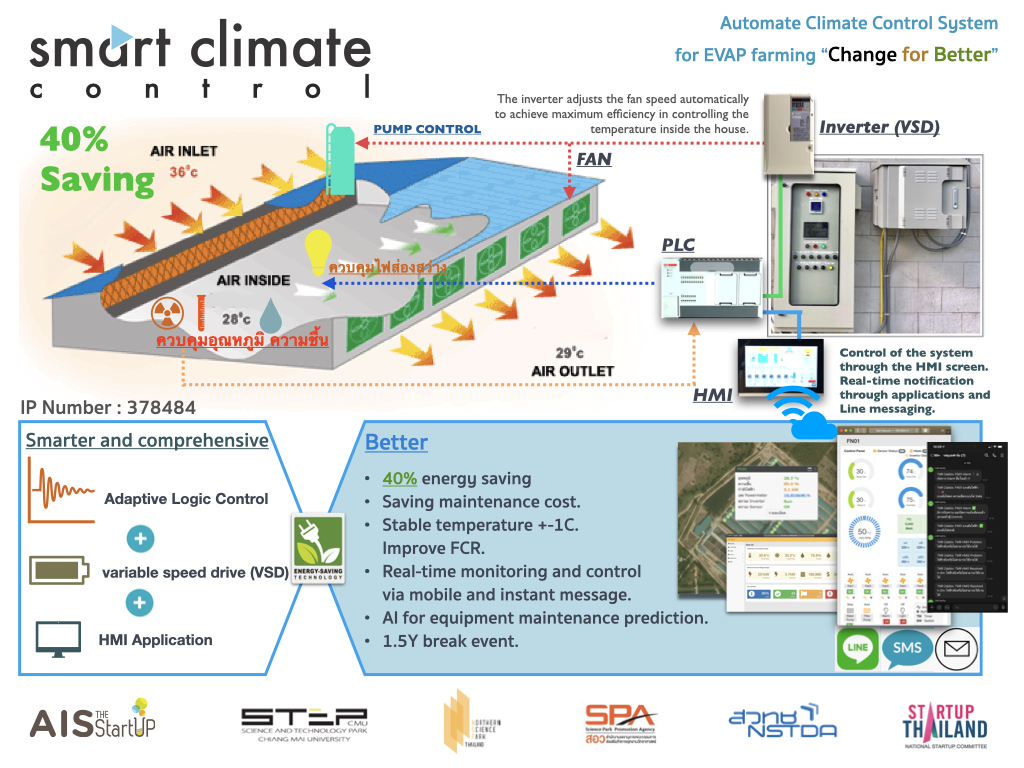

energy saving, cost-effective, and comprehensive

SMC : Smart Climate Control system helps farmers optimize energy usage, monitor temperature and humidity, and control EVAP ventilation fans remotely. Transform to a smart farm today to reduce energy consumption, improve crop yields, and reduce costs.

Reduce energy consumption

Remote Monitoring and Control

Customizable for additional sensors

Message notification system

Flexible to be customized

Smart farm hardware setup

- Inverter

- Edge computing with PLC and HMI touch screen.

- Automatic starter and evaporative fan control (Multi Fan)

- Automatic water pump and heater starter.

- Local and online alarm via instant message

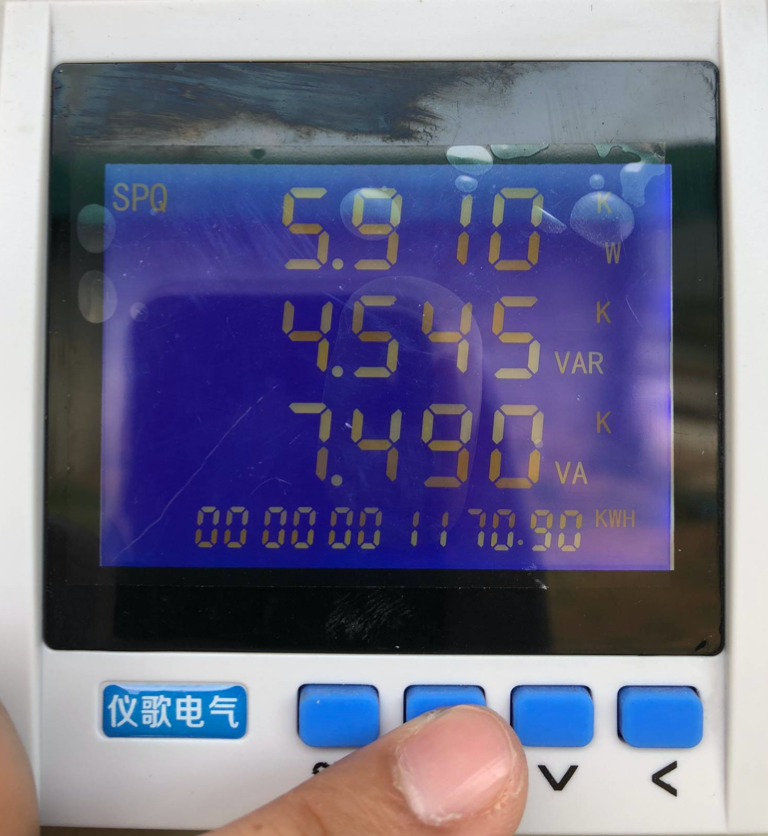

- Digital Power Meter

- Monitoring and control everywhere with webapplication.

- Support various sensors (Temp, Humid, Ammonia, Wind speed, Water, Load-cell etc.)

- All data on the cloud.

In partnership with

Traction / Performance

Our invention has been awarded by the Innovation Accelerator Program of the Science Park Promotion Agency (SPA) of the Ministry of Science and Technology, Thailand, and the Science & Technology Park Chiangmai University (CMU STeP).

Third Prize

at the Startup Thailand Pitching Challenge 2018.

Silver Medal Award

Agricultural Innovations ITEX2018, Malaysia.

Third Prize

2018 NSP Awards.

SMC Functions

Main Function

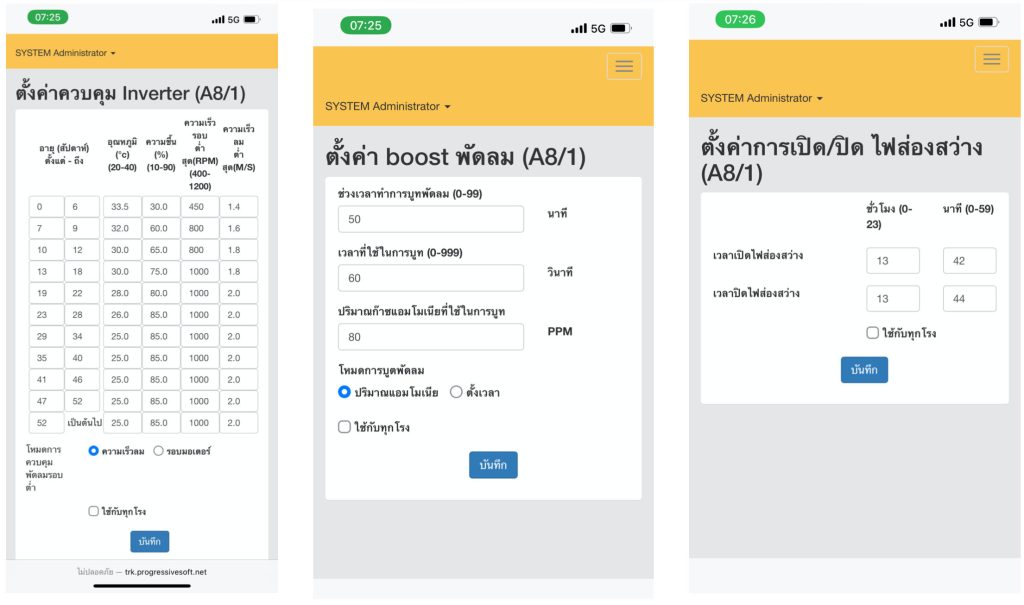

Cabinet with an automatic temperature control system controlled by inverter. It consists of:

- Yaskawa V1000 inverter

- PLC for automatic control

- Automatic start and control kit for multi-fan

- Automatic start and control kit for cooling pad

- Automatic start kit for heater

- Lighting control with automatic on-off timer

- Temperature and humidity sensors Inside the house

- Alarm lights and signals

- 7-inch HMI touchscreen connected to the control cabinet

- Digital power meter for automatic measurement of current and voltage.

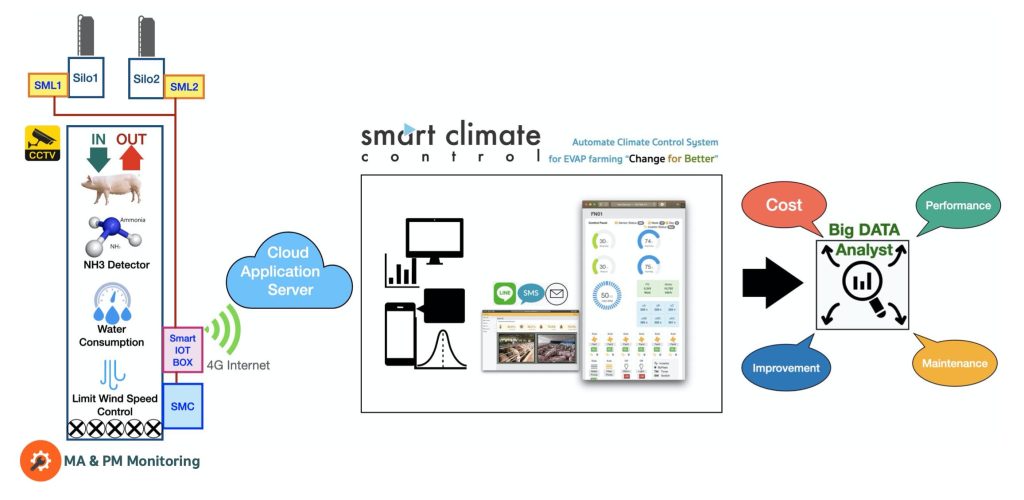

Add-on Option

Management Monitoring and Control Options:

- Recording and displaying the number of pigs entering, deaths, and causes of death inside the enclosure.

- Processing and displaying data from the wind speed sensor.

- Processing and displaying data from the turbine flow meter to calculate water usage rate.

- Processing and displaying data from the ammonia gas sensor.

Closed circuit camera system inside the greenhouse, linked to a cloud application for centralized monitoring. - Automatic control system for opening/closing and controlling various devices in the breeding facility, such as water/feed line system, curtain system, feeding winch system, window shutters, biogas pump, and others, utilizing the I/O channels to receive data and distribute power to various endpoint devices.

MA (Maintenance Alert) and PM (Preventive Maintenance) options:

- Detecting and processing alerts for maintenance cycles of system equipment, such as bearing replacement intervals, motor replacement intervals, fan blade replacements, and other devices that require condition-based detection and alerting for scheduled maintenance.

- Displaying reports on equipment cycles/lifespans and sending advance maintenance notifications through cloud applications and Line messaging.

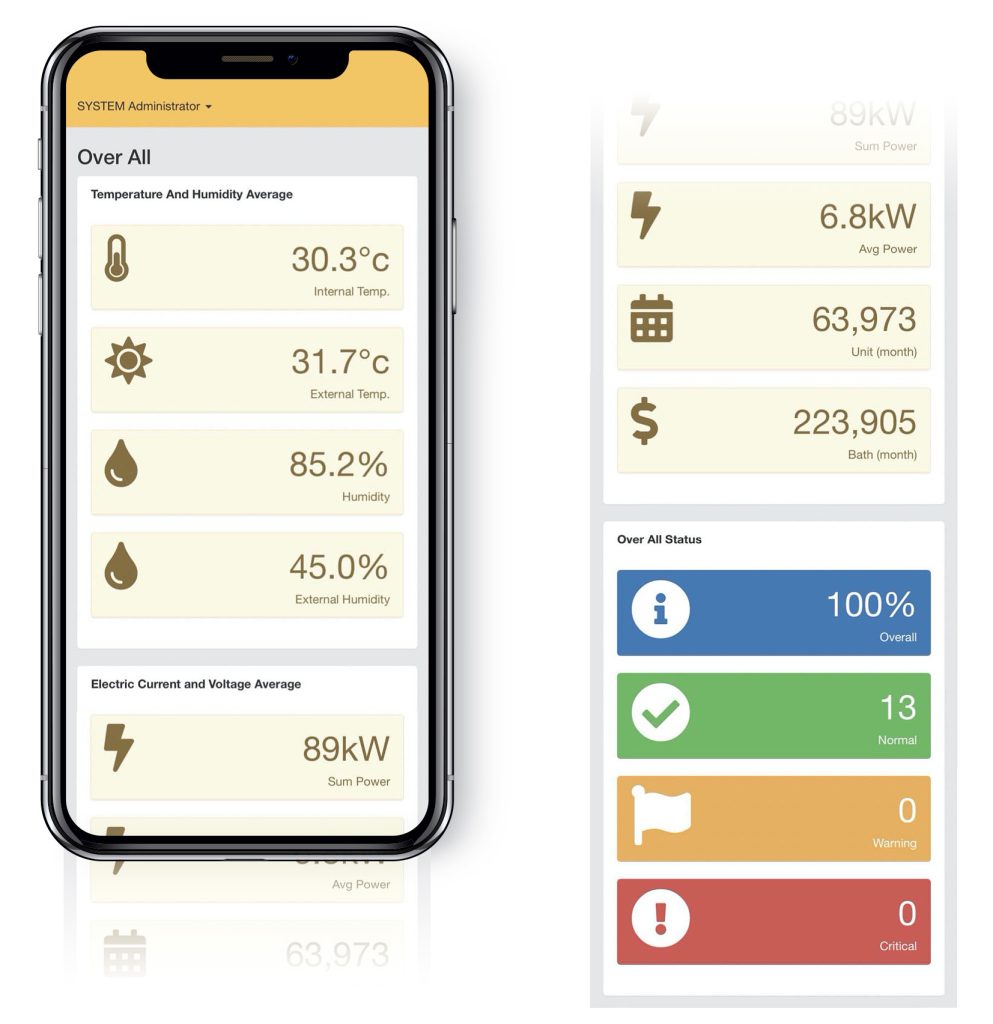

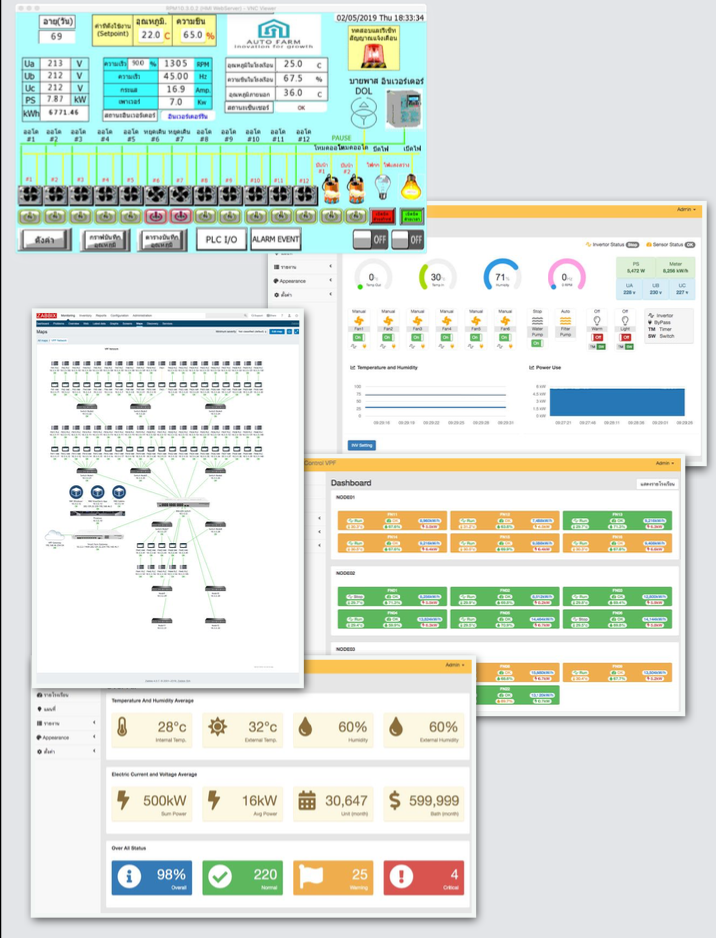

SMC Smart Farm Cloud Application

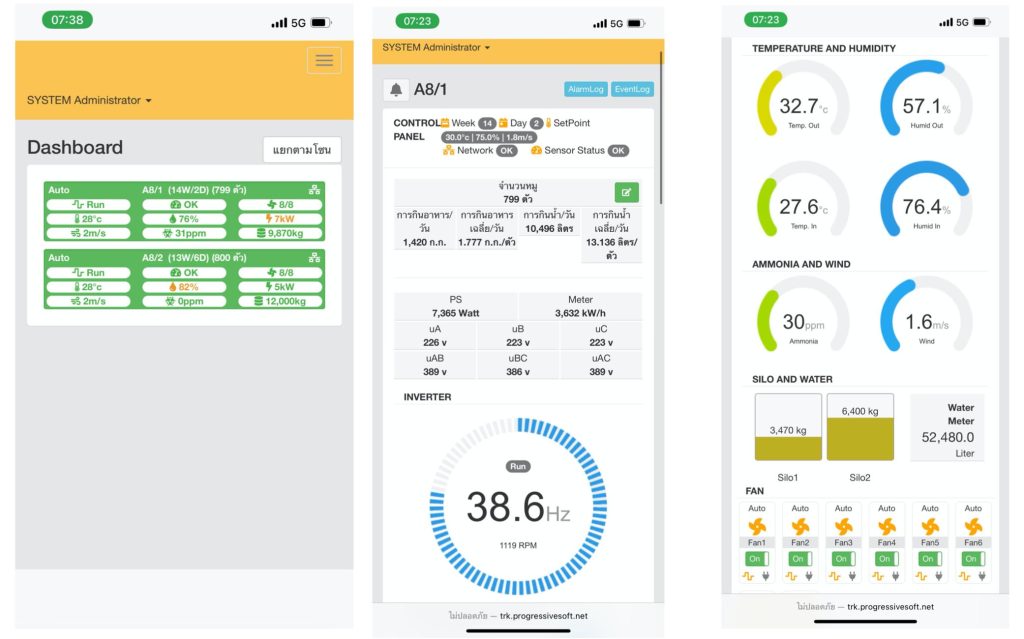

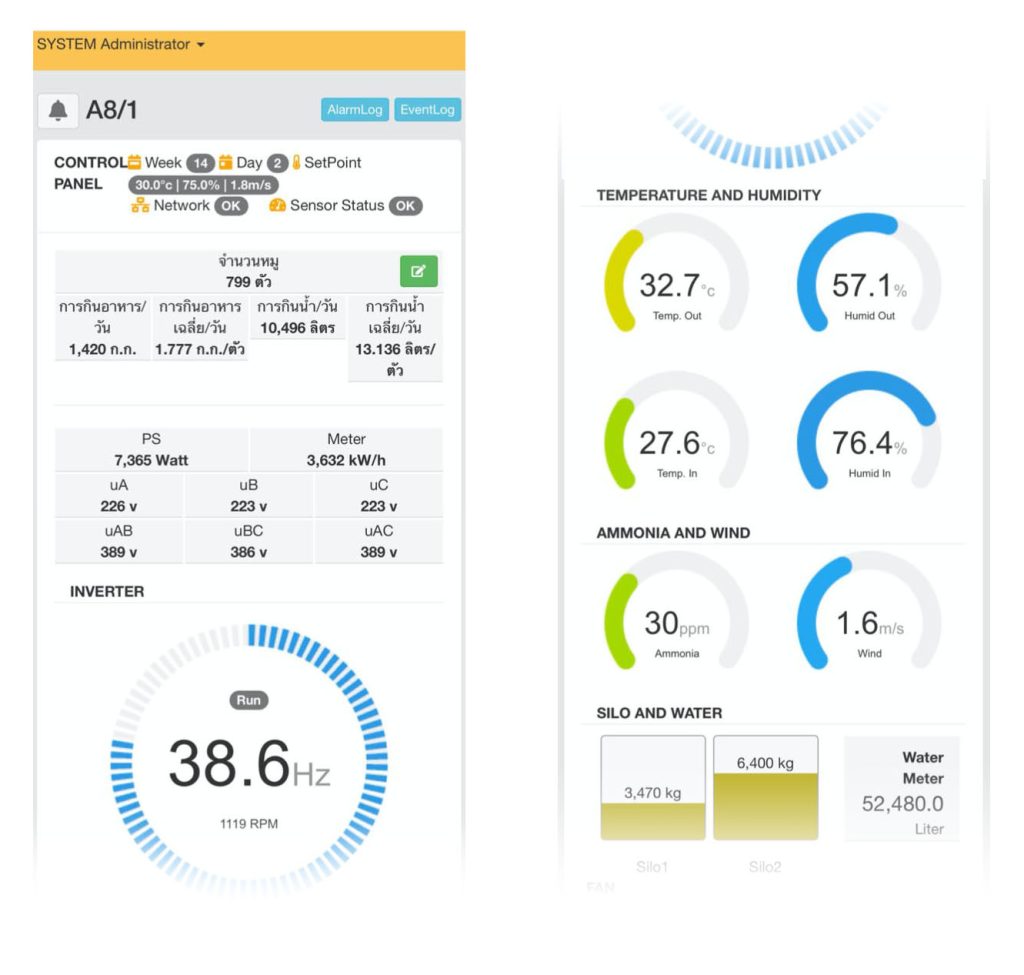

System Monitoring & Control

The main page provides an overview of the average state of all houses

Dashboard showing the number of houses and a page showing details of Monitoring & Control of that house

Dashboard showing the number of houses and a page showing details of Monitoring & Control of that house

Input data details of changes in the number of animals in each house.

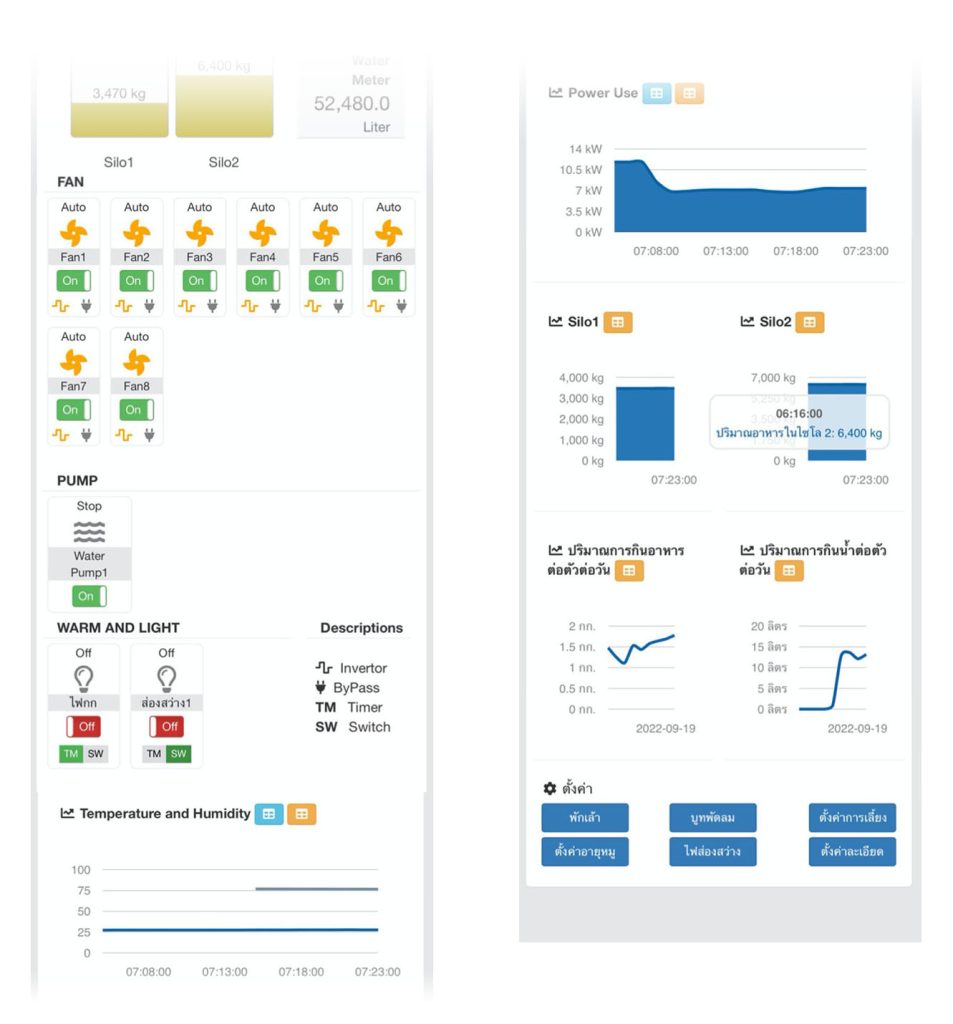

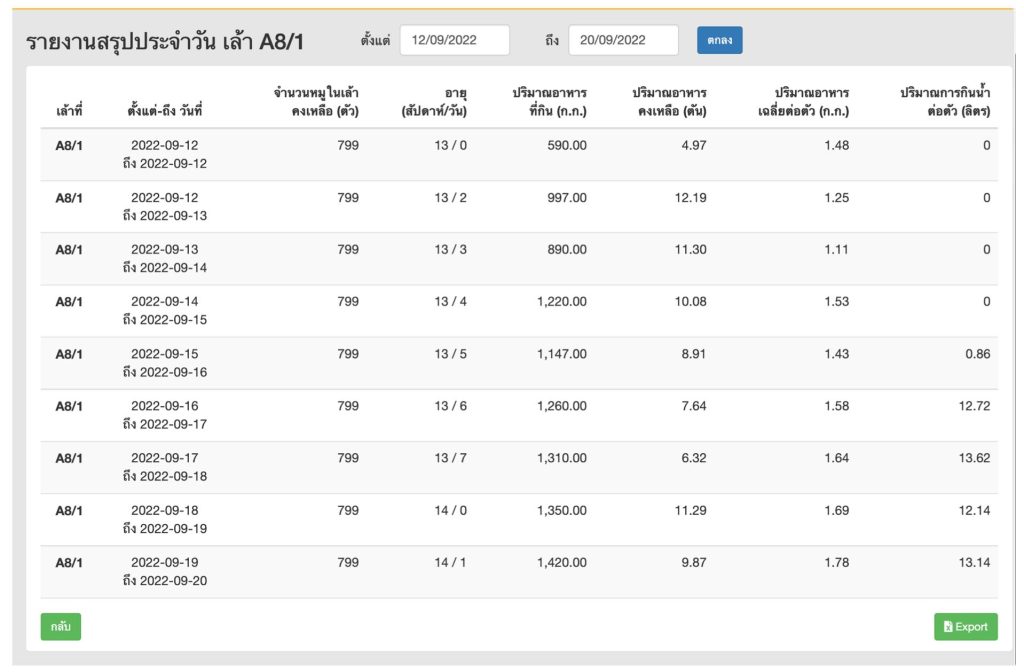

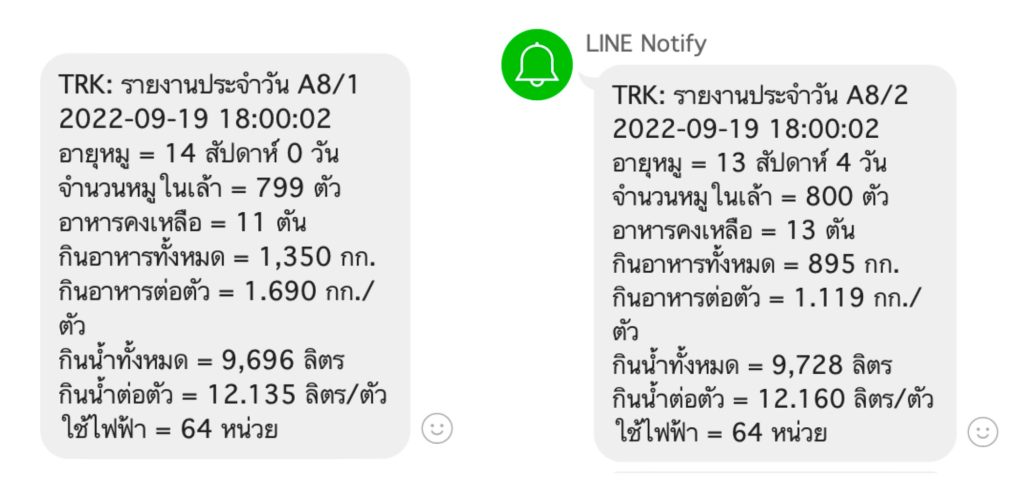

Daily report page showing details of changes in the number of animals, food consumption, and water usage in each house.

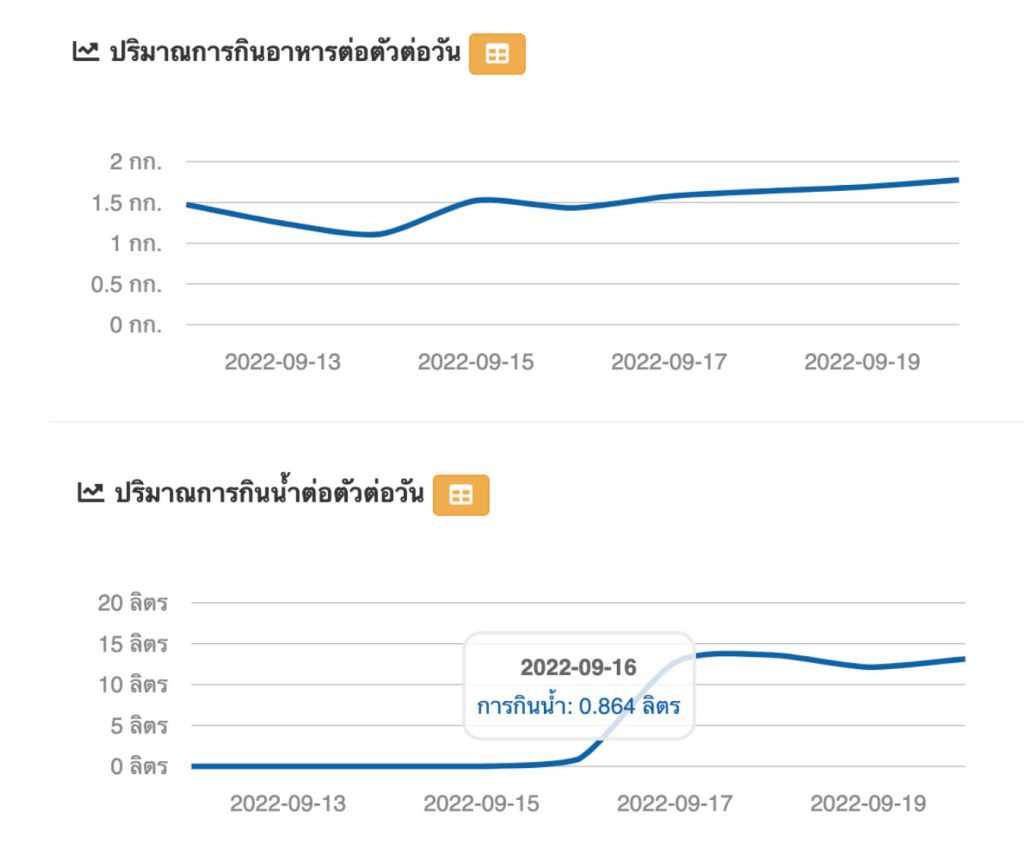

Graph showing the average daily consumption of food and water per animal, for tracking and comparing with standard values.

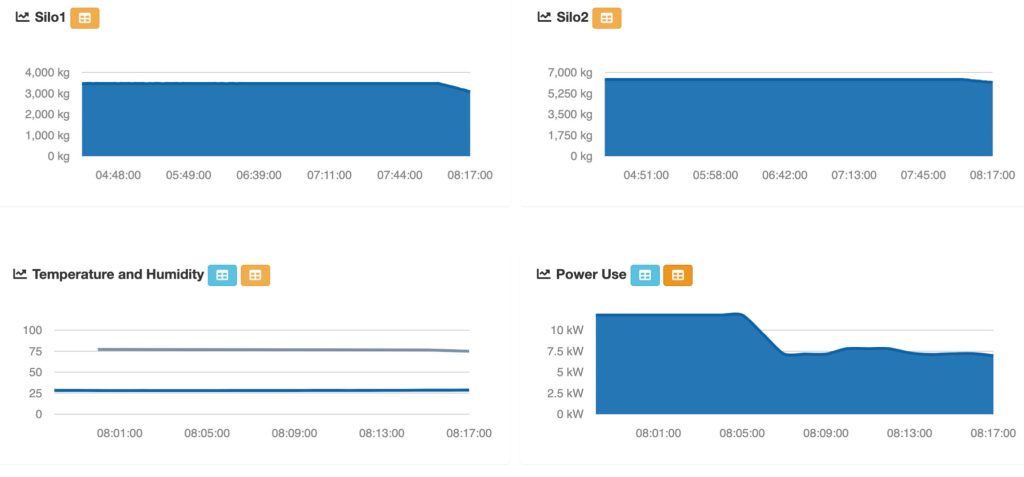

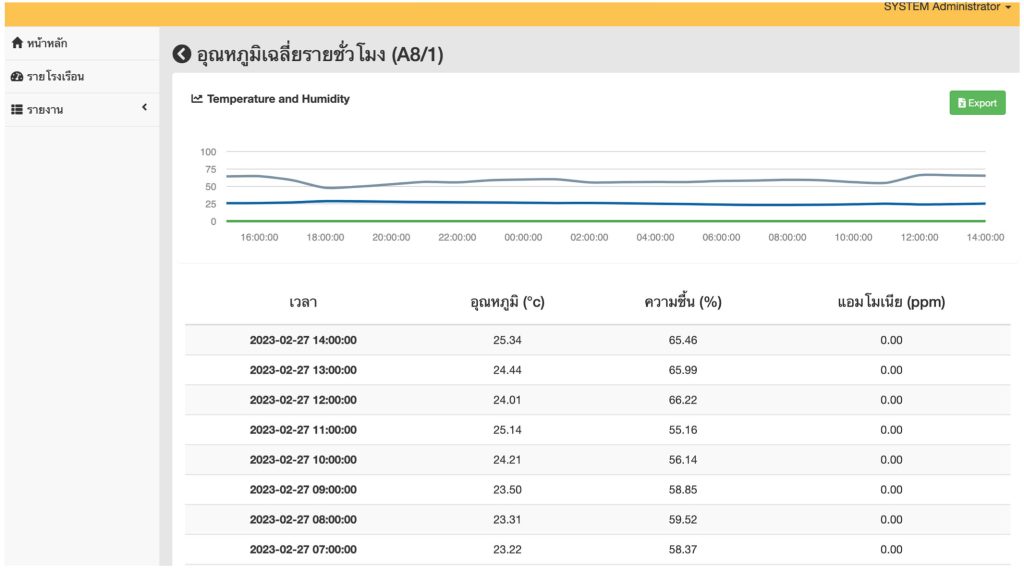

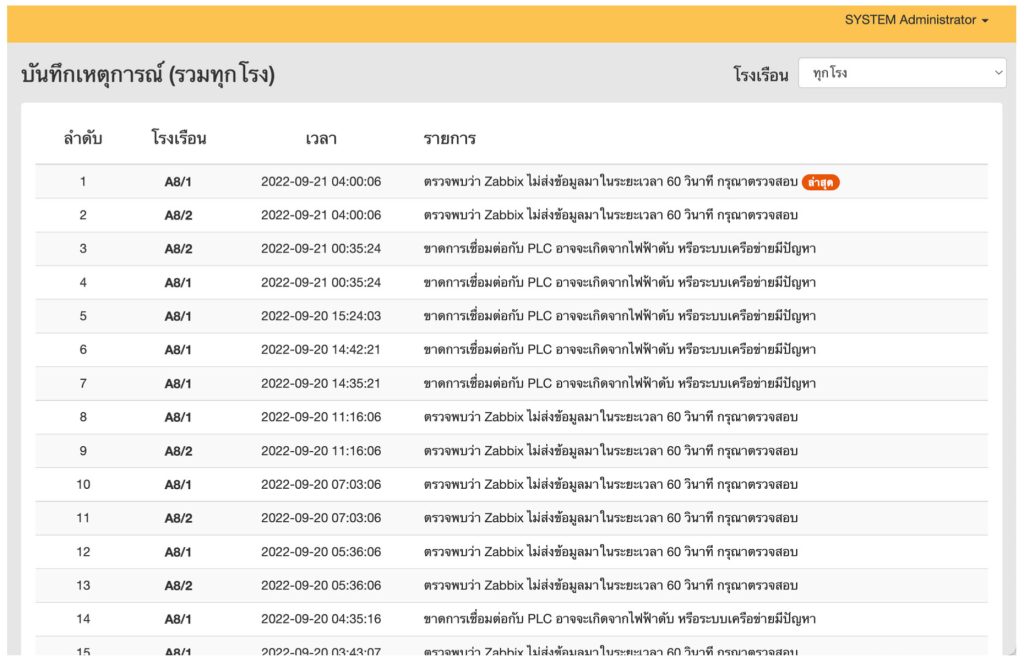

All data logs will be stored in the system for future analysis, such as temperature, humidity, and various incident occurrences.

The settings page allows detailed configuration for each time interval of feeding, and enables copying of the configuration to other remaining facilities, making the work more convenient.

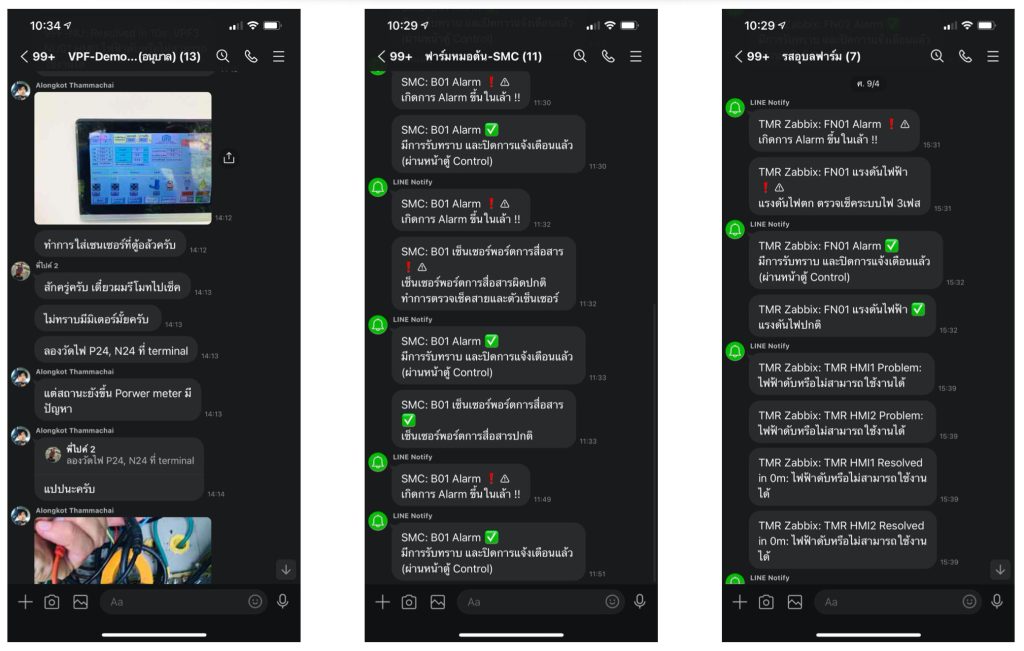

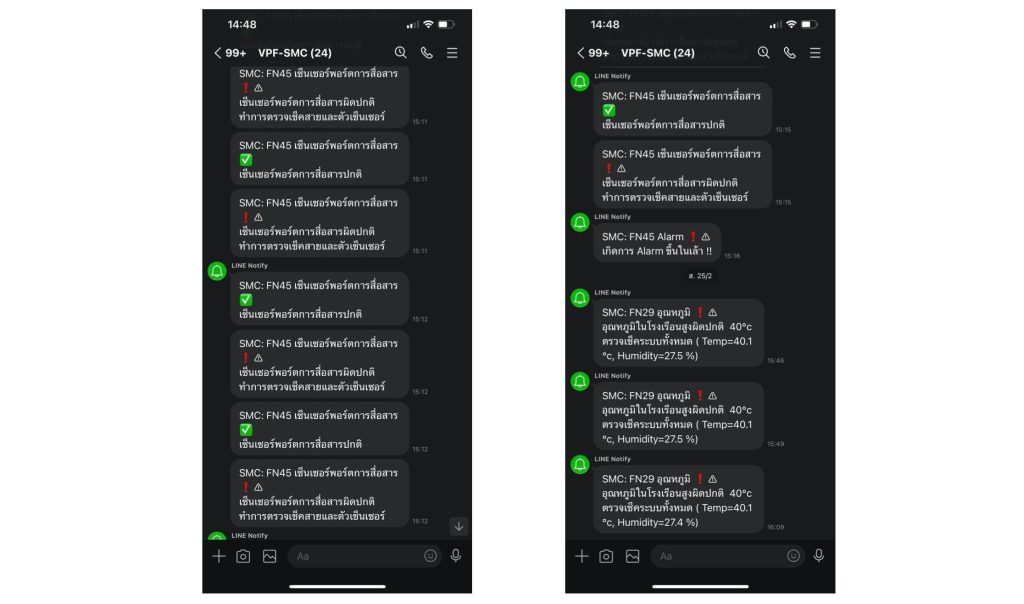

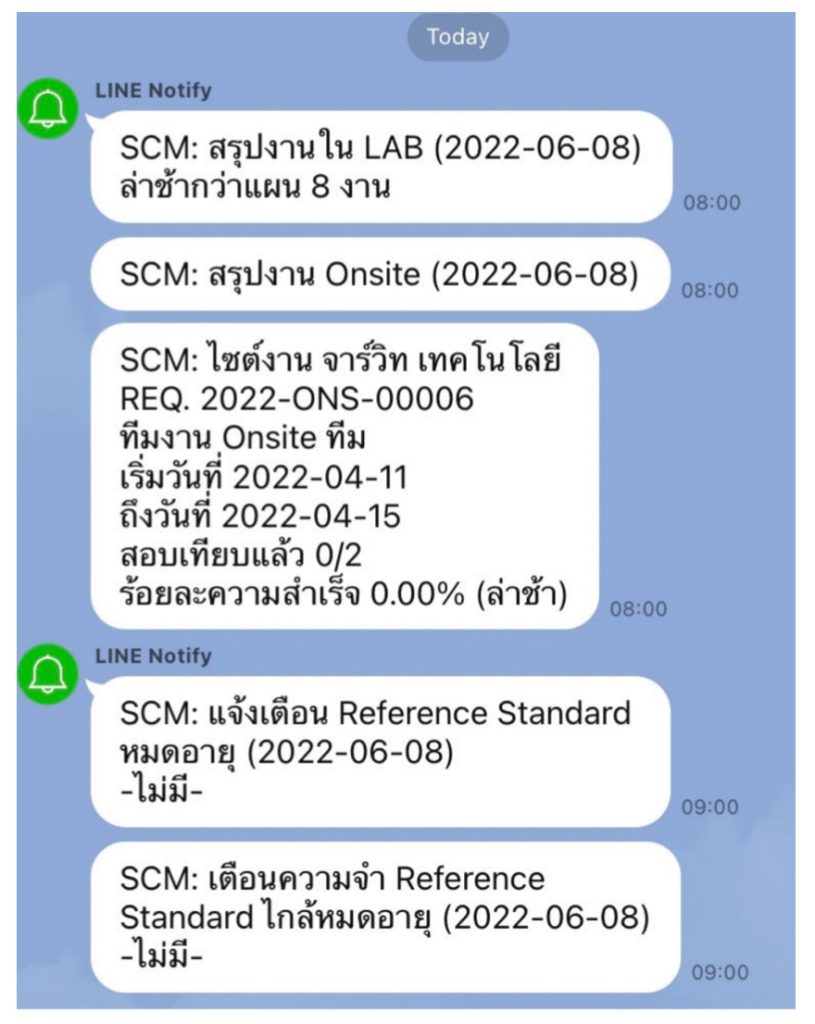

Notification

Real-time alerts via the Line application that can add, adjust parameters, or address issues.

MA & PM

Real-time alerts via the Line application that can add, adjust parameters, or address concerns related to MA and PM.

Smart

Streamline the process of inspection, monitoring, and notification, extending to wireless control of operations through both local and online.

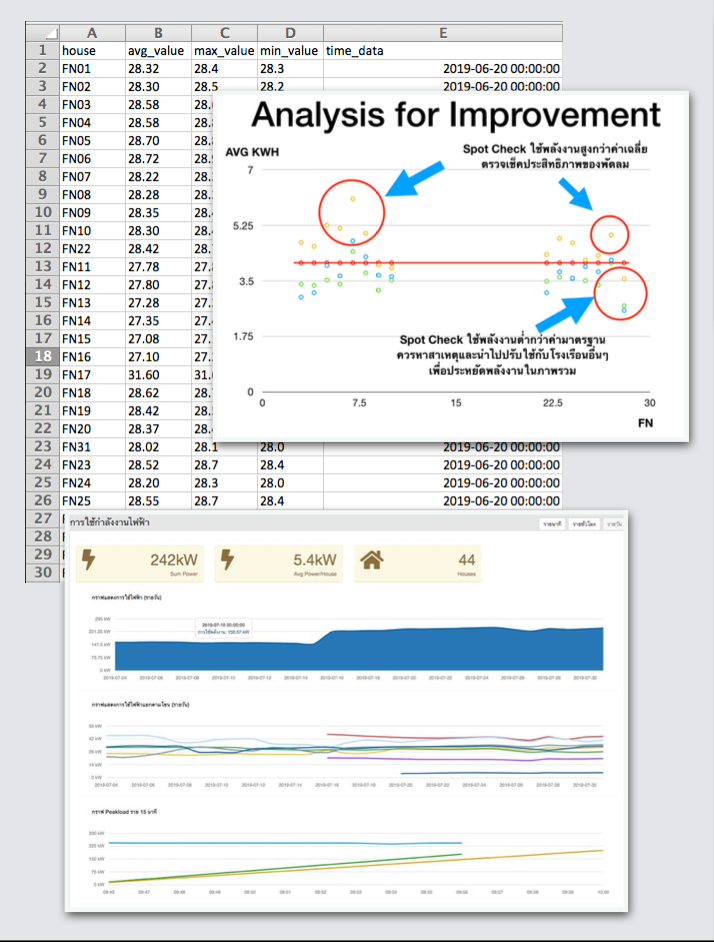

Big Data

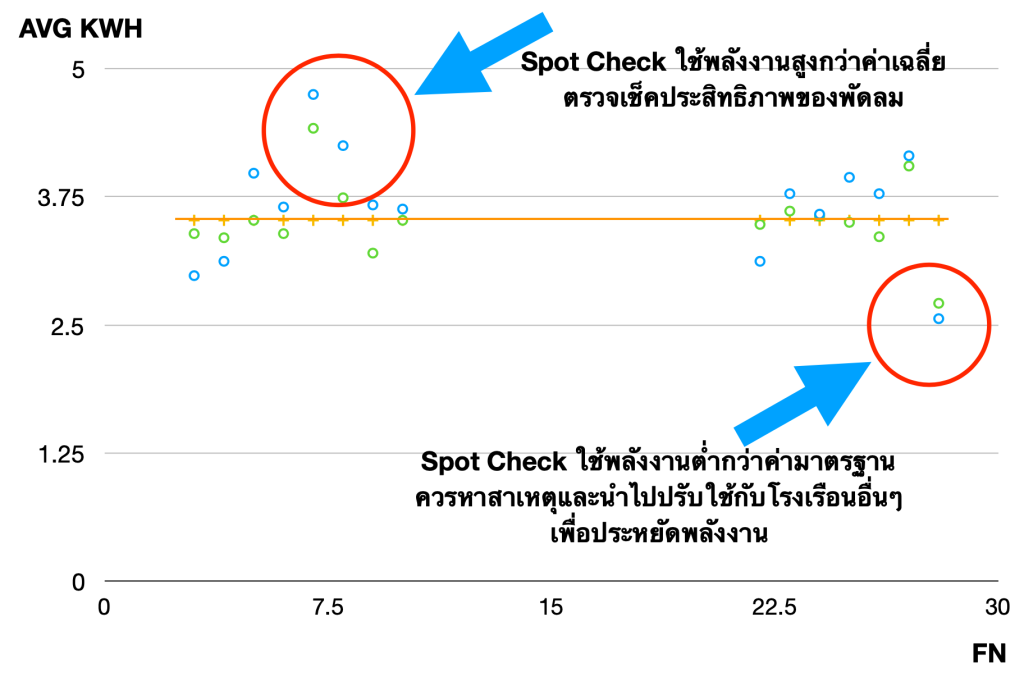

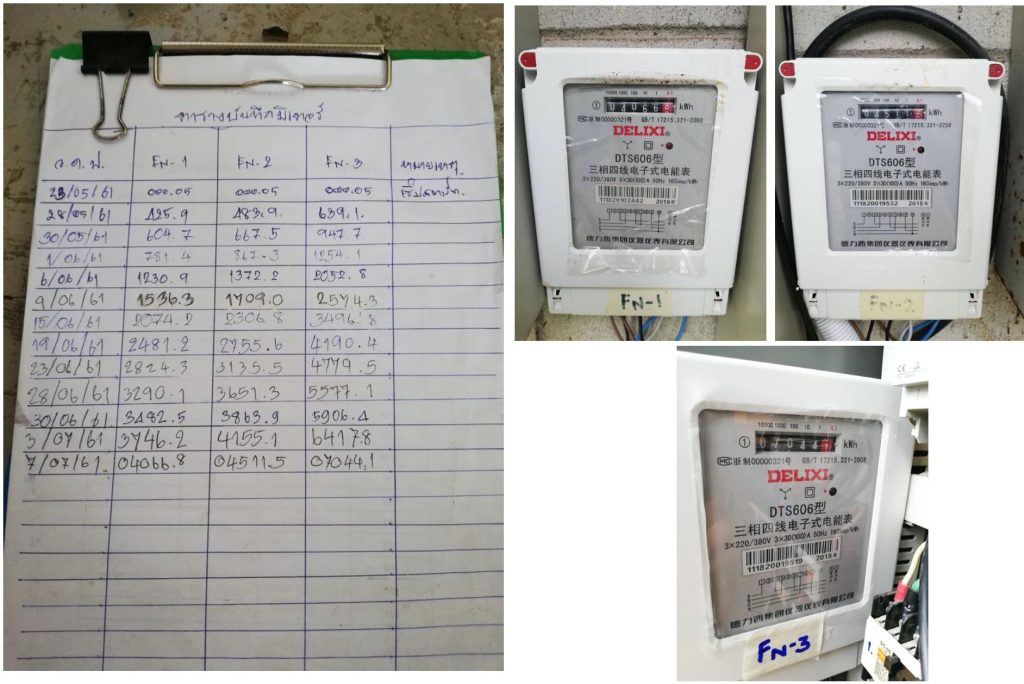

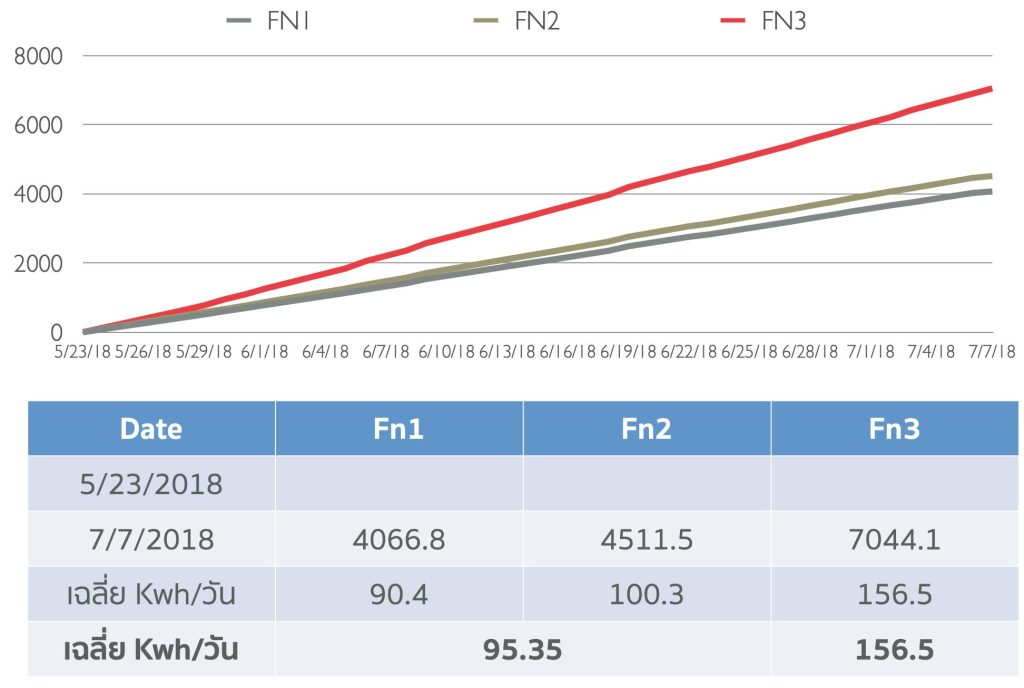

Utilize data or export it to support analysis, pig farming, production, equipment maintenance, efficiency detection through data-driven reports and graphs.

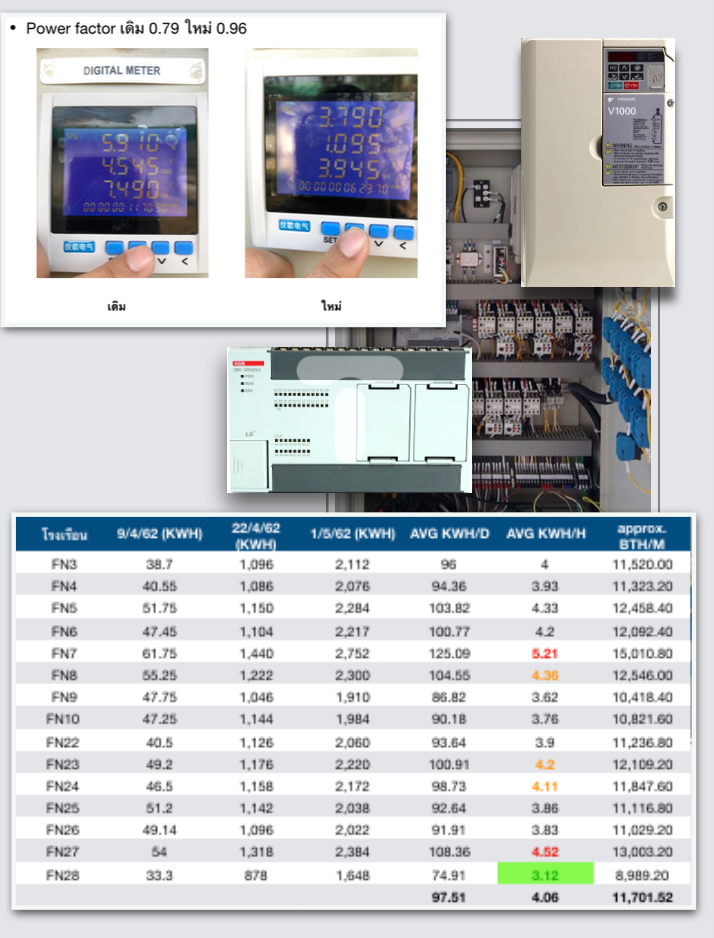

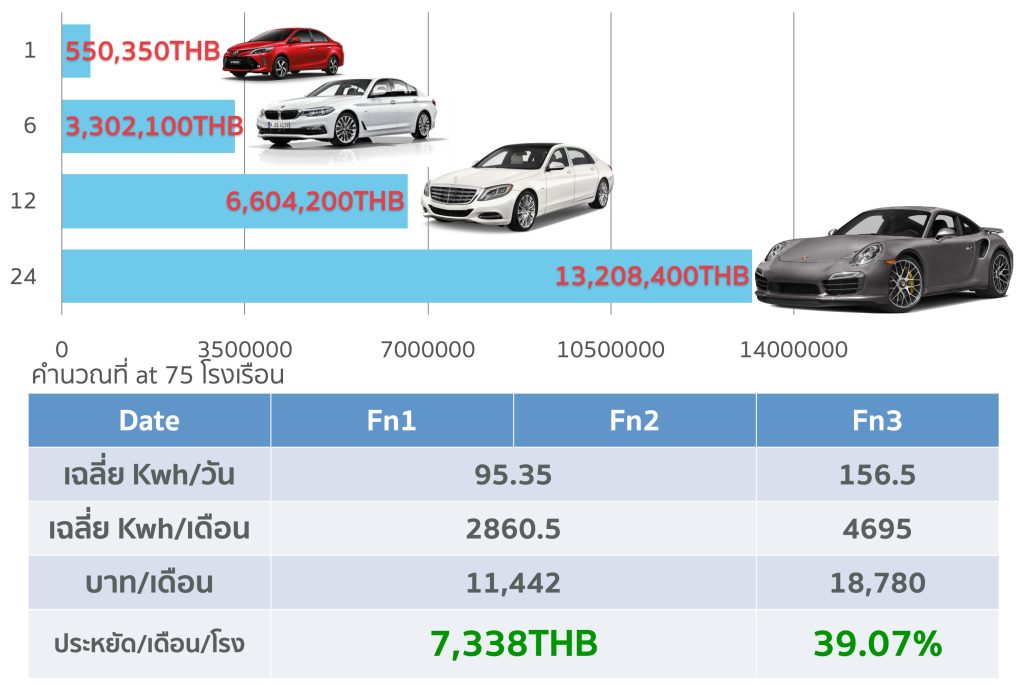

Energy Saver

Saving energy usage by 30-40% and improve power factor.

Benefit

Start operating the new system on April 8, 2019 at 6:00 p.m.

System operation started on April 8th, 2019, at 18:00.

Average energy consumption was 3.52 KWH/H. Comparing it to the energy usage statistics of the previous equipment during the experimental period from May 5th, 2019, to September 19th, 2019, which was 6.72 KWH/H, it was found that energy consumption could be reduced by (6.72-3.52)/6.72*100 = 47.61%.

Estimated energy savings for the month of April 2023 (from April 8th to April 30th, 22 days, 15 houses):

Previous equipment: 6.72 * 22 * 24 * 15 = 53,222.40 KWH (212,889.60 THB)

SMC: 3.52 * 22 * 24 * 15 = 27,878.40 KWH (111,513.60 THB)

In summary, energy consumption has decreased by 25,335 KWH, resulting in savings of approximately 101,340 THB.

Old system Power factor 0.79

SMC Power factor 0.96

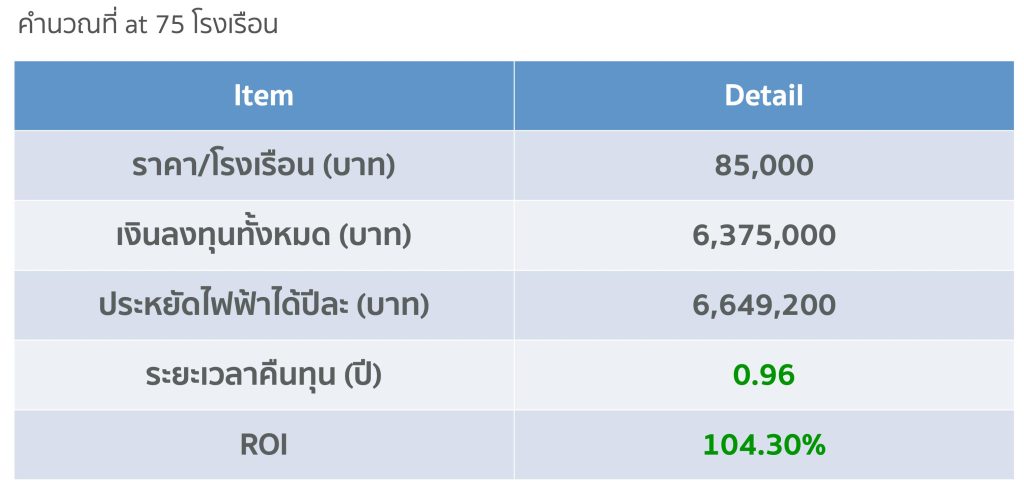

Analysis for Improvement

Result if farm already inverter system

Result

Benefit

Finance

Testimonial

I saved electrical cost more than 50% from 21,000 THB/month (674USD) to 6,200 THB (199USD), it’s well worth it. (FCR 2.45)

Pakorn Keawtong

CPF Pig farmer role model.

My poultry house for 20,000 birds used energy consumption only 1,507 units (kWh) average energy cost 0.4THB (0.013USD) per bird. !! (FCR 1.48)

Kittikon

CPF Poultry farmer

Since the installation of the system, it has made the work of the team of technicians much easier. They can now monitor various values through their mobile phones, including receiving notifications when there are system issues.

Surasit

VPF Pig Farm operation

With Respect To Each Customer